A grand sonnerie, petite sonnerie, and minute repeater with proprietary sapphire crystal gongs plus a tourbillon, stop-seconds function, and COSC and Poinçon de Genève certifications comprise Chopard‘s latest tour de force timepiece. Unveiled today at Dubai Watch Week, it marks the most complicated chiming watch from the Swiss watchmaker and the first time Chopard has done a grand sonnerie. The L.U.C Grand Strike required 11,000 hours of research and development, of which 2,500 hours were invested in fine adjustments during the prototyping phase alone to ensure the many components work together. Its dial-less display puts this horological expertise front-and-centre where many of the 686 components—all packed into a 43 by 14.08 mm 18-karat ethical gold case—can be seen in action.

Despite its obvious complexity, the Grand Strike is thoughtfully constructed for ease of use. Case in point: The slider, typically used to activate the minute repeater, has been upgraded so the user can easily change between three modes from one touch point. Here, you can switch between “G” for the grand sonnerie to “P” for the petite sonnerie to “S” for silence—all shifting via an openworked disc. Just beneath is the fluted bassiné-style crown where you can activate the minute repeater via a button in the center or wind up the barrel for the movement on one side and the barrel for the sonnerie mechanism on the other side. On the lower half of the dial lies the 60-second tourbillon at 6 o’clock with a small seconds on the cage which comes with a stop seconds function for precise time setting.

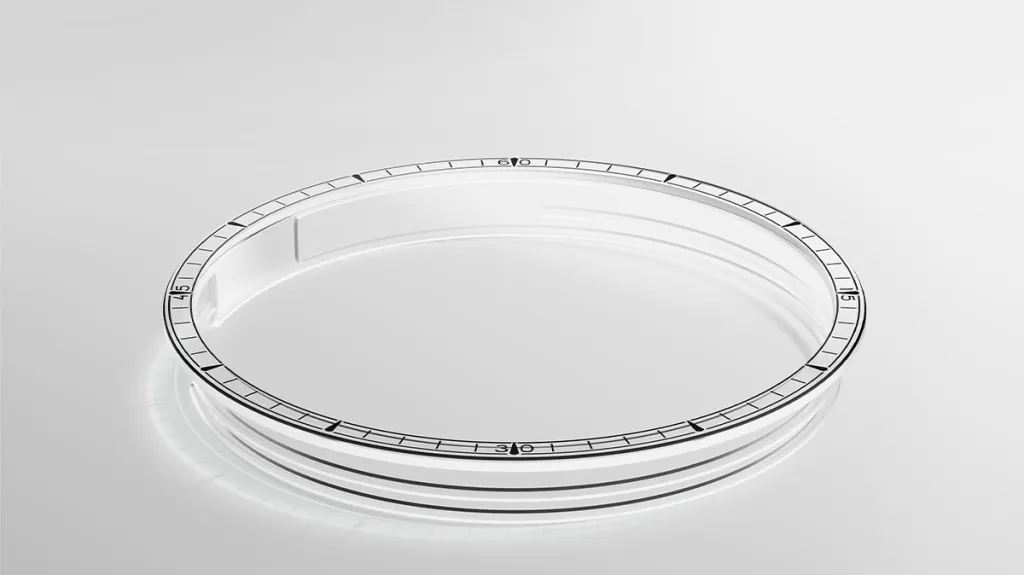

But what makes this watch really sing are its sapphire crystal gongs operating with two steel hammers (pictured top left between 9 and 11 o’clock). The manufacture worked with the Haute Ecole du Paysage, d’Ingénierie et d’Architecture (HEPIA) for the analysis and nuances of its signature chime with notes tuned to emit a C#-F♮ chord. Traditionally, a sonnerie chime emits sound via hammers that strike steel gongs which transmit acoustic energy through vibrational waves traveling through the dial crystal and creating sound through the air, which can result in energy loss via the gong attachments, movement, and case, thereby decreasing the effect of the sound. Here, Chopard combines the gongs and the dial crystal which are machined from a single monobloc of sapphire crystal, so that when they are struck by the hammers they vibrate in concert with the dial crystal directing the sound toward the exterior and avoiding the usual loss of acoustic energy through the movement and case. The result is a crisper, clearer sound.

Furthermore, the sapphire crystal gongs use a square cross-section to maximize contact with the hammers and channel vibrations into distinct, layered modes, yielding a richer and more textured chime than traditional round steel gongs. Combined with the material’s monocrystalline hardness—which resists deformation and produces an ethereal, resonant tone—this construction gives Chopard’s sonneries their unmistakable symphony.

Chopard developed five new patents to support and safeguard its exceptional sonnerie: two ensure intuitive, worry-free use by allowing the chime to be activated or modes to be switched at any time without harming the movement, while three focus on performance, including an energy-efficient clutch that reduces torque and extends the sonnerie’s power reserve (a minimum of 12 hours in grand sonnerie mode), a safeguard that blocks activation when torque is insufficient to prevent incomplete chimes, and a redesigned hammer geometry that minimises shock to the sapphire gongs without compromising sound quality.

Beyond its extensive technical achievements, which have a total of 10 patents (some of which are still pending), its Poinçon de Genève certification is the icing on the cake. The prestigious hallmark is awarded to watches assembled and regulated in the Canton of Geneva meeting the strictest standards of craftsmanship, quality, construction integrity, durability, and finishing. The components have been hand finished with the main plate and bridges in German silver. The same material can be found in Chopard’s Full Strike watches and is only used in their exceptional creations. And, while the maison considered using sapphire for the tourbillon bridge, it ultimately landed on stainless steel, which they felt was more impactful.

Despite the incredible amount of haute horology packed inside, the movement manages 70 hours of power reserve. It is both a work horse and a work of art. Furthermore, it is proof that, Chopard’s manufacture in Fleurier, Switzerland is positively flourishing.

The piece is not a limited edition, but will be limited in production to the tune of approximately just 3 pieces a year.