Bentley is going to pick up Speed Six production right where it left off.

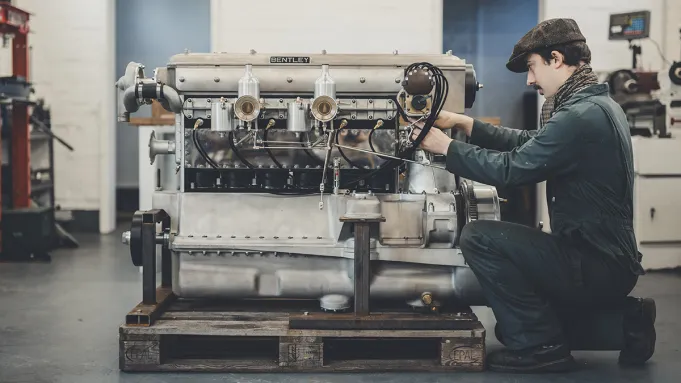

The British marque’s bespoke unit, Mulliner, has begun building new, working examples of its most successful race car. The new Speed Sixes will be manufactured from the ground up by hand, using the same tools and methods its workers employed nearly a century ago.

The continuation cars will be the first Speed Sixes the automaker has built since the original vehicle was discontinued at the beginning of the 1930s. The factory race car was powered by a powerful 6.5-litre cylinder mill that helped push the “Bentley Boys” to victory at the 24 Hours of Le Mans in 1929 and 1930. During the two years the car was in production, 182 examples rolled off the line, but the automaker announced first Speed Six Continuation Series at the Goodwood Festival of Speed in 2022 and committed to building a dozen more.

Image courtesy of Bentley

We imagine most of the new Speed Sixes are destined to be put on display concours events around the globe, but they’re being built to be driven just like the original cars. Each is being built from scratch using the original schematic and engineer notes as a guild. Bentley still has a couple of old Speed Sixes lying around, which are both being used as “templates” to check dimensions, materials, and components, according to the automaker. Additionally, the team at Mulliner is using period-correct tools, fixing, and techniques to manufacture the cars, which explains why it takes 10 months to build each example.

The most complex component of the vehicle is the six-cylinder mill, which consists of over 600 bespoke parts. The continuation cars are also set to include the same race improvements that helped them earn their checkered flags at Le Mans. And, because Bentley has gone all in on customisation in recent years, each customer has been offered a personal fitting for their car and is being given their choice of period-correct interior and exterior finishes.

Image courtesy of Bentley

Unsurprisingly, the Speed Six Continuation Series comes with a sky-high price tag. When the car was first announced, Bentley said that each example would cost around US$2 million (HK$15 million), or more than eight times the starting cost of the open-top Continental GTC. Of course, since the entire production run has sold out, anyone who didn’t manage to wrangle a built slot can expect to spend even more to get their hands on a new Speed Six.